The Ultimate Guide to Hot Foil Stamping and Cold Foil Stamping in Cosmetic Packaging for 2024

5 minutes reading

Hot foil stamping and cold foil stamping are two of the most sought-after techniques in the industry, known for their ability to add a premium, luxurious touch to product packaging. This detailed guide explores both methods, providing in-depth insights to help you choose the best foil stamping technique for your cosmetic brand.

What is Foil Stamping?

Foil stamping is a distinctive printing process that uses metallic or pigmented foils to create an eye-catching visual effect on packaging materials. This technique is highly favored in the cosmetic industry for its effectiveness in attracting customer attention through shiny, reflective qualities that signify luxury and high quality.

Quick View:

| Category | Hot Foil | Cold Foil |

| Pros | – Greater depth and textured feel with the impression of the die into the substrate – More variety in foil finishes and foil patterns (e.g., holographic designs) – Shinier foil as the die “irons” the foil super smooth when pressed – More cost-effective for shorter runs, even with the cost of a die – Best way to apply foil to heavily textured uncoated stocks – Common and easy to find print suppliers with hot foil capabilities |

– Best for labels, flexible packaging, larger print runs, or print runs with multiple colors of foil – Can be used with intricate designs, including gradients and even incorporated into images – Allows for creative overprinting and achieving multiple hues with a single foil application |

| Cons | – Requires a custom-made stamp or die – Slower process than cold foiling – Can get costly with multiple colors of foil – Might require design simplification to work with the foil |

– Not all manufacturers have cold foil technology – Slightly duller foil finish compared to hot foil – Limited to smoother substrates (no felt finish uncoated stocks) |

| Best Fit For | – Luxury packaging, especially on heavily textured stock – Business cards and stationery – Wedding invitations – Any project where a premium, tactile feel is desired |

– Labels – Flexible packaging – Larger print runs on smoother substrates where cost-effectiveness, multiple colors of foil, and speed are crucial |

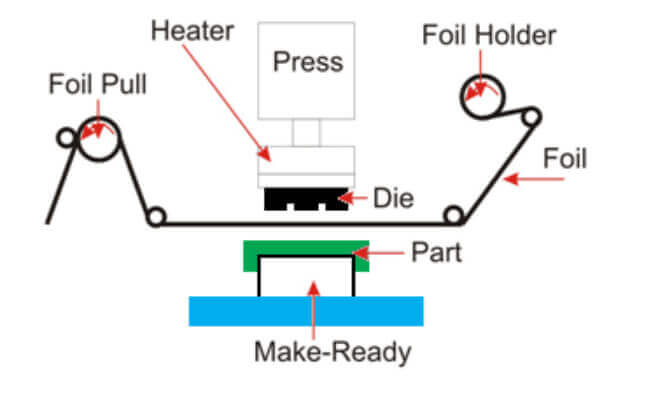

| Additional Notes | – Requires heat and pressure to transfer the foil onto the substrate – Often used for small to medium-sized print runs due to the setup costs – Offers durability and longevity, making it suitable for high-end products – Typically involves a more labor-intensive setup process |

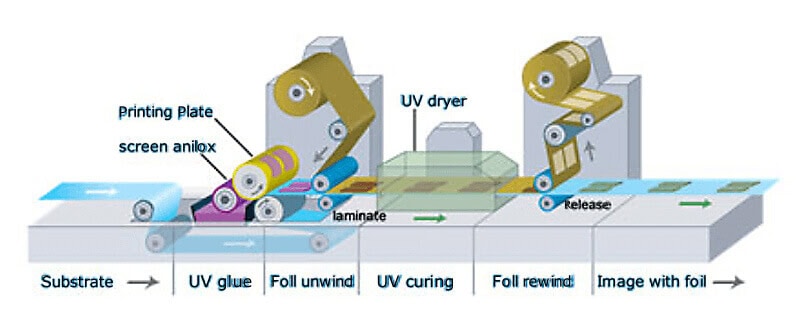

– Utilizes an adhesive applied via printing, followed by a cold foil application and curing with UV light – Ideal for high-speed, high-volume printing processes – Allows for seamless integration into existing printing workflows, especially for complex designs – More environmentally friendly as it uses less energy and fewer materials – Often used for items requiring quick turnaround times and efficient production |

Hot Foil Stamping: The Touch of Luxury

The Process:

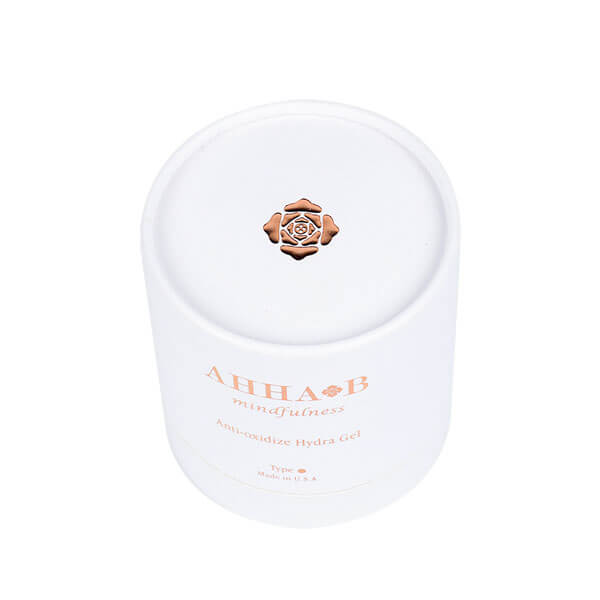

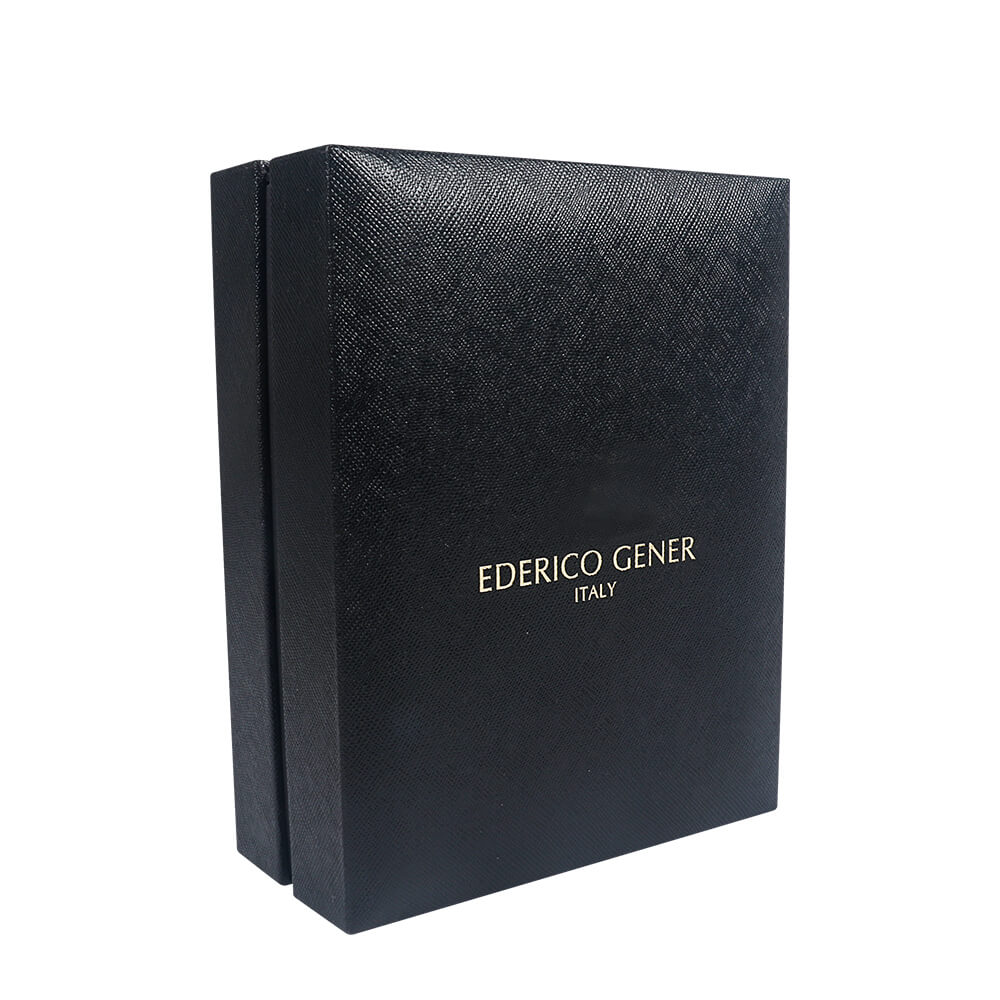

Hot foil stamping involves the application of metallic or pigmented foil onto the packaging material using a heated die. The die is carved with the desired design and is heated before being pressed onto the foil. As pressure is applied, the foil bonds with the surface, transferring the die’s design onto the packaging.

Benefits:

- Precision and Elegance: Offers unrivaled precision in imprinting intricate designs, perfect for logos and detailed graphic elements.

- Texture and Depth: Adds depth to the packaging with a slight embossing effect that enhances tactile appeal.

- Wide Range of Materials: Effective on various substrates including paper, cardboard, leather, and plastic, providing flexibility in packaging choices.

- Diverse Finish Options: Available in numerous finishes such as matte, gloss, metallic, and holographic styles to match brand aesthetics.

Ideal Applications:

- Luxury skincare products, boutique makeup lines, and other high-end cosmetics where branding relies heavily on an image of exclusivity and premium quality.

Cold Foil Stamping: Efficient Glamour

The Process:

Cold foil stamping is a modern alternative that involves applying a thin layer of foil to the packaging material pre-printed with a UV-curable adhesive. The foil is then cured under UV light, adhering it to the substrate without the need for heat.

Benefits:

- Speed and Scalability: Allows for rapid production, making it suitable for large runs and tight deadlines.

- Cost-Effectiveness: More economical than hot foil stamping, it provides a luxurious look without the high costs.

- Overprinting Capabilities: Enables vibrant color printing over the foil, offering limitless design and customization options.

- Environmental Considerations: Produces less waste and uses fewer resources, aligning with eco-friendly packaging initiatives.

Ideal Applications:

- Seasonal cosmetics offerings, promotional beauty products, and any cosmetic line where cost and time constraints are a priority without sacrificing aesthetic appeal.

Selecting the Right Foil Stamping Method for Your Cosmetic Brand

When it comes to choosing between hot and cold foil stamping for your cosmetic packaging, several operational factors should guide your decision-making process. Here’s a practical breakdown of these considerations to help you align your choice with your brand’s operational needs and goals:

#1. Design Specificity and Complexity

- Hot Foil Stamping: If your packaging design includes intricate details, such as fine lines or small, complex graphics, hot foil stamping is the ideal choice. This method allows for sharp, precise applications that highlight the smallest details, enhancing the perceived quality and luxury of the product.

- When to Choose: Opt for hot foil stamping when launching premium products that demand high-end packaging to reflect the quality of the contents, like luxury skincare serums or high-fashion cosmetic lines.

#2. Budget Considerations

- Cold Foil Stamping: For brands looking to manage costs effectively, especially when producing large volumes, cold foil stamping offers a budget-friendly alternative. This method reduces material costs and operational fees, making it suitable for larger production runs.

- When to Choose: Ideal for extensive product launches, seasonal items, or promotional campaigns where keeping costs down is as important as attractive packaging.

#3. Production Speed and Volume

- Cold Foil Stamping: This method excels in scenarios where speed is critical. Cold foil stamping’s faster setup and curing times facilitate quicker turnaround, which is crucial for meeting tight market deadlines and handling large orders efficiently.

- When to Choose: Select this method when your distribution schedule demands rapid production, such as for timely market introductions or restocking popular items.

#4. Sustainability Objectives

- Cold Foil Stamping: If your brand prioritizes environmental responsibility, cold foil stamping is the more sustainable option. This method generally involves fewer consumables and less energy consumption compared to hot foil stamping, aligning with green business practices.

- When to Choose: Cold foil stamping is suitable for eco-conscious brands that market their products based on environmental values, aiming to appeal to a customer base that values sustainability in their purchases.

#5. Material Compatibility

- Hot Foil Stamping: Certain packaging materials that are sensitive to heat or require a more delicate approach benefit from hot foil stamping’s precise application and quality finish.

- Cold Foil Stamping: More versatile with non-traditional and thinner substrates, cold foil is adaptable to a wider range of material types without the risk of damage from heat.

- When to Choose: Evaluate the substrate you plan to use for your cosmetic packaging. For heat-sensitive materials or when flexibility in substrate choice is needed, cold foil stamping may be more appropriate.

By carefully considering these operational aspects, you can choose the most suitable foil stamping method to enhance your cosmetic products’ appeal while adhering to your brand’s functional and ethical standards. CustomBeautyBox.com can assist in evaluating these factors with you, ensuring that your packaging is not only beautiful but also optimally aligned with your production capabilities and brand values.

Which One Would You Like to Choose for Your Brand?

Both hot and cold foil stamping have distinct advantages that can enhance the aesthetic value and marketability of cosmetic products.

By understanding each method’s strengths and limitations, cosmetic brands can make informed decisions that align with their marketing strategies, budget, and brand ethos. At CustomBeautyBox.com, we are dedicated to helping you explore these options and implement the best packaging solutions that reflect the essence of your brand.

Our expertise in the latest packaging technologies and trends will ensure that your products not only stand out on the shelf but also resonate with your target audience, ultimately driving sales and brand loyalty.