3 Most Recommended Finishing Process in Cannabis Packaging Boxes

A concise overview of cost-effective surface finishing processes in paper packaging

If we describe paper packaging as an outfit for a lady, then surface finishing is the whole makeup. It makes her stand out and endow her with a full personality.

Surface finishing, also known as a surface treatment in the paper packaging industry, involves a lot of techniques, genre, and skills, which is not what we should concern about. At the end of the day, how they are achieved is not something a customer should spend time on; What to achieve is what matters.

It happens to most of our customers that they cannot settle on a plain and normal printing paper box. And when they found that adding some surface finishing to an unromantic paper box is like bringing a second life to this box, some might go from one extreme to the other. Occasionally one customer would reach out and say: hey, mate, let’s add UV, embossing, and soft-touch coating with a nice gold foil stamping…whatever you have, I want my box be standing out from the crowd. It’s understandable from a customer’s viewpoint. The initial intention is to bring more delight to our packaging box, thus “Much” isn’t always equal to “Good”, sometimes less is more.

Speaking of which, that’s why I would like to bring up this topic: how we could spend the least to achieve our ideal packaging boxes without “overreacting”, in a buyer’s viewpoint instead of factory technicians’. Now let’s go exploring what’s the most used and best “cost-effective” finishing process in the marijuana packaging industry,

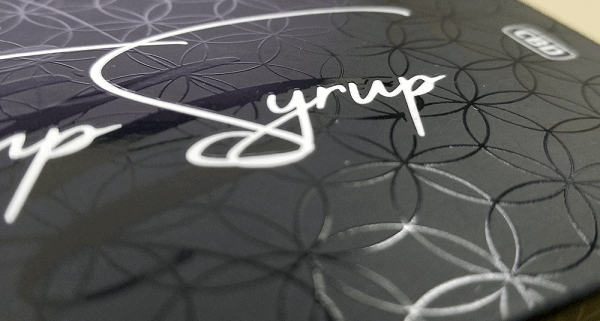

1, Spot UV Finishing Process

This must be the top 1 most used surface process in the printing & packaging business. Undoubtedly there are lots of “jargon” and diverse genre when we talk about UV, though simply put, we can group them into 2 major UV finishing types: Spot UV with ink and Spot UV without Ink.

Let’s say, with a normal CMYK printing box, you want to make your LOGO, images or texts pop out from the flat surface, Spot UV with ink can be applied in this case. It can make a colored logo/image/area/ texts pop out from the box surface while keeping their original color. This is Spot UV with ink.

On another occasion, if you want to add some extra texture without having extra colors to the original box face, a spot UV without ink can be considered. It’s also known as “blind spot UV” For instance, your brand has some symbolic lines want to emphasis except for your LOGO, images, and texts, you could just add some lines or other elements on the box surface.

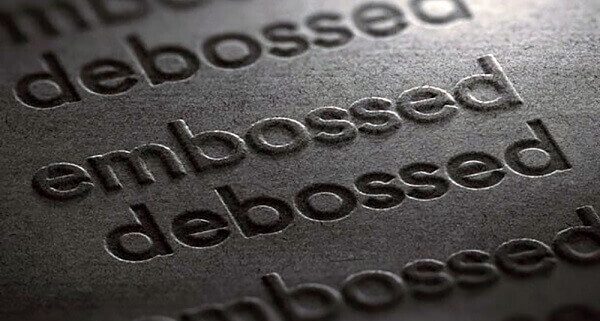

2, Embossing and Debossing

The picture tells everything, embossing and debossing is majorly adapted when you want to emphasize your LOGO or certain texts. It comes with a touch feeling for “exterior” and “interior” texture, which makes the whole box much more decent.

Embossing and debossing cannot be used on thin art paper, in other words, it cannot achieve that “touch feeling” when the paper is not thick enough.

Thus, this is very popular in handmade craft paper that is mostly made of cardboard.

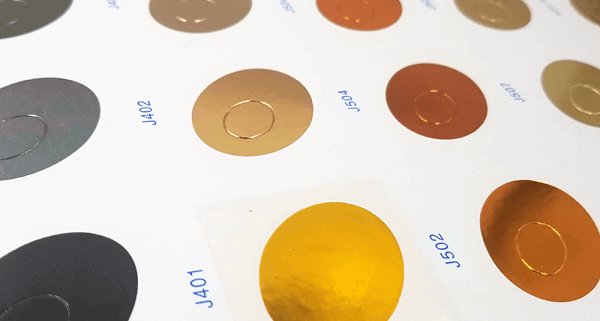

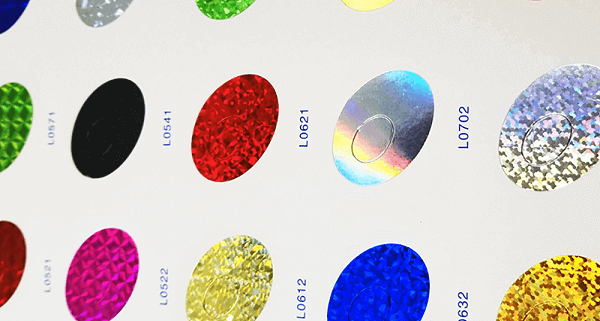

3, Gold/Silver Foil stamping

Literally, it’s just foiling gold or silver foil on a certain part of a box. However, what’s interesting is that it is not limited to only Gold and silver when it comes to color options. There is a range of colors for choosing.

What’s more, the foil stamping process itself has also a “special finishing” effect. Some can achieve a laser look. This is how they look like,

To make it an end, there are also lots of other surface treatment options in the paper printing and packaging industry, but not all of them are recommended for marijuana packaging boxes, beauty box packaging, and all other packaging industry. The design and concept for your brand is always the initial and essential part to focus on. And these three surface finishing process is the most ideal and efficient way to instantly delight the whole design of your packaging.

The old saying “Seeing is believing” is also applicable in the packaging industry. A real sample speaks for himself. Always keep smooth and accurate communication with your packaging supplier is always the key to successful packaging.