Aqueous Coating: Eco-Friendly Shield for Beauty Packaging

1 What is Aqueous Coating? The Science Behind the Shine

Aqueous coating (often abbreviated AQ coating or water-based coating) is an environmentally friendly protective layer applied to printed materials like custom cosmetic boxes.

Made of water, acrylic polymers, and additives, it replaces harmful solvents with H₂O as its primary carrier — a key reason it’s favored by eco-conscious beauty brands.

How It Works:

Applied as a liquid, it flows evenly over surfaces through offset or flexographic presses.

As water evaporates during drying, the acrylic polymers form a thin, flexible film that resists scratches, fingerprints, and moisture.

Key Terms Explained:

Flood Finish (“Full Coverage”): Coating the entire surface for uniform protection.

Spot Coating: Selectively coating areas (e.g., logos) to reduce costs while highlighting key elements.

Aqueous Lining: A distinct process where coatings act as internal barriers in food-grade packaging (e.g., lipstick tubes).

Why Beauty Brands Love It:

✅ Meets FDA indirect food contact standards for lip care and skincare boxes.

✅ Recyclable with standard paperboard, aligning with zero-waste initiatives like Lush’s packaging strategy.

2 7 Game-Changing Applications in Cosmetic Packaging

From minimalist skincare boxes to glitzy holiday gift sets, aqueous coatings solve critical challenges:

| Application | Example | Benefit |

| Anti-Scratch Luxury | High-end perfume boxes (e.g., Tom Ford) | Protects metallic foils from shipping damage |

| Soft-Touch Texture | Charlotte Tilbury’s velvet-finish compacts | Creates premium unboxing experiences |

| Scented Packaging | Glossier’s limited-edition body oil boxes | Adds subtle vanilla or floral notes |

| Child-Resistant | CBD skincare boxes with tactile warnings | Meets compliance via raised matte coatings |

| Climate Resistance | Clean beauty brands shipping to humid regions | Reduces warping vs. uncoated paperboard |

| Color Consistency | Fenty Beauty’s neon pink packaging | Prevents ink oxidization over time |

| Sample Sachet Sealing | Sephora’s mini product pouches | Water-resistant edges prevent leaks |

Case Study: Kylie Cosmetics reduced returns by 18% by switching to matte aqueous-coated mailers that resist scuffs during shipping.

3 Choosing the Right Aqueous Coating: Types, Costs & Limitations

Finish Types

| Coating | Aesthetic | Best For | Cost/Sq.Ft |

| Gloss | Mirror-like shine | Highlighting bold logos (e.g., Morphe) | 0.08–0.08–0.08–0.12 |

| Matte | Velvety, non-reflective | Minimalist skincare (e.g., The Ordinary) | 0.10–0.10–0.10–0.15 |

| Soft Touch | Silky texture | Luxury gift sets (e.g., Dior) | 0.15–0.15–0.15–0.20 |

| Satin | Subtle pearl shimmer | Bridal makeup collections | 0.12–0.12–0.12–0.18 |

When Not to Use Aqueous Coating:

Extreme durability needs: For packaging requiring chemical resistance (e.g., nail polish boxes), UV coatings are better.

High-heat environments: Temperatures >120°F may soften the coating.

Pro Tip: Combine coatings! Spot-gloss logos on matte boxes (used by Rare Beauty) create a striking visual contrast.

4 Inside the Aqueous Coating Process: From Printer to Dryer

Step-by-Step Workflow

1) Design Prep: Avoid coating areas needing foil stamping or embossing (coating first can block adhesion)

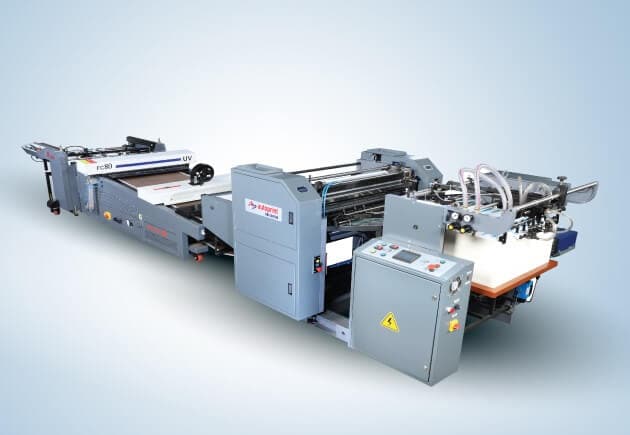

2) Press Setup: Use in-line coaters on offset printers (e.g., Heidelberg Speedmaster).

3) Application:

- Anilox Rollers: Control coating thickness (4–8 gsm typical for beauty boxes).

- Drying: Infrared dryers evaporate water in 15–30 seconds (critical to prevent paper warping!).

4) QC Checks: Verify smoothness with microgloss meters (60° gloss units for standard matte).

Tech Specs:

- Ideal substrate: C1S or C2S paperboard (18–24 pt thickness).

- Drying time formula: 2 seconds per micron coating thickness.

Common Mistakes:

⚠️ Over-coating (>10 gsm) causes cracking.

⚠️ Applying over unsealed metallic inks leads to dulling.

5 Aqueous vs. UV Coatings: Which Should Your Brand Choose?

Let’s break it down simply:

| Factor | Aqueous Coating | UV Coating |

| Scratch Resistance | Good (survives 50+ scratches) | Excellent (handles 75+ scratches) |

| Drying Time | Dries in 30 seconds | Dries almost instantly |

| Color Over Time | Stays clear for years | Might yellow in sunlight |

| Eco-Friendliness | ♻️ 95% plant-safe, breaks down naturally | ♻️ 40% (uses some chemicals) |

Costs Made Simple:

- Machines Cost: UV needs expensive equipment (50k+). Aqueous is cheaper (10k).

- Big Orders: Aqueous is 30% cheaper at 10k+ units (e.g., 2,500 vs. 3,500 per 5k boxes).

Who’s Using What?

68% of small beauty brands pick Aqueous for smaller orders – it’s wallet-friendly and green!

- Choose Aqueous If: You’re eco-focused, do small batches, or want a velvety/matte finish

- Choose UV If: You need super tough packaging (like frequently handled boxes) and have a bigger budget.

Think of it like skincare:

Aqueous = gentle, everyday moisturizer 🌱

UV = heavy-duty sunscreen for extreme conditions ☀️

6 Sustainability Deep Dive: How Aqueous Coatings Impact Your ESG Goals

Circular Lifecycle

1) Production: Uses 60% less energy vs. UV (per Green Packaging Institute).

2) Recycling:

- Fully compatible with PCR paperboard (tested by DS Smith).

- Breaks down in 3–6 months in industrial composters vs. 100+ years for laminates.

3) Carbon Footprint: Generates 0.8kg CO2/kg vs. 2.5kg for solvent coatings.

Green Certifications to Highlight:

- OK Compost INDUSTRIAL: Validates compostability.

- ECOGRADED™: Confirms low VOC emissions (<0.5%).

Caution: “Biodegradable” claims require ASTM D6400 testing – partner with suppliers who certify compliance.

7 Future Trends: Where Aqueous Coatings Are Heading

- Smart Coatings: Temperature-sensitive inks for seasonal packaging (e.g., snowflakes appearing in winter).

- Antimicrobial Formulas: Post-COVID demand for “self-sanitizing” makeup boxes.

- Biobased Polymers: Coatings made from algae or cornstarch (pioneered by L’Oréal).

Ready to Elevate Your Brand with Aqueous-Coated Packaging?

At [Custom Beauty Box], we’ve helped 500+ brands achieve 48% faster unboxing engagement with our eco-friendly coatings.

📞 Speak to an Expert: Click here to schedule a free packaging consultation.