Die Cut Packaging: Benefits and Applications Explained

Die cut packaging is a custom packaging method that uses a metal die to cut materials like paper, cardboard, or plastic into precise shapes and designs.

This process allows businesses to create unique, tailored packaging that enhances product presentation, provides excellent protection, and reflects a brand’s identity.

Die cut packaging is popular for cosmetics, personal care products, and luxury items, offering benefits like sustainability, versatility, and cost-efficiency.

It allows for custom features such as windows, compartments, and intricate shapes, making it a valuable choice for businesses aiming to stand out in a competitive market.

In this post, let’s explore everything about die cut packaging! Let’s dive in.

1. Understanding Die Cut Packaging: What It Is and How It Works

Die cut packaging is a method of creating custom-shaped packaging using a specialized die to cut materials into specific shapes.

This process allows brands to create packaging that is not only functional but also tailored to their product’s unique dimensions and branding.

The die cutting process uses a sharp metal die that is shaped like the desired packaging design.

The die is then pressed onto the chosen material, typically cardboard, paperboard, or other flexible materials, to create precise cuts.

These cuts can be intricate, allowing for complex shapes, windows, folds, and perforations that suit different packaging needs.

For instance, die cut paper packaging boxes are commonly used in the beauty industry for packaging items like lip gloss, soap, and custom press-on nails.

The advantage is clear: it’s highly customizable, and you can have packaging that matches your brand’s image while providing maximum protection for your products.

2. The Advantages of Die Cut Packaging: Why It’s the Ideal Choice for Custom Designs

Die cut packaging offers several significant advantages that make it a popular choice for many industries, especially in the cosmetic and personal care sectors.

First and foremost, die cut packaging allows for unique and precise shapes that align with a brand’s visual identity.

Whether you’re looking for a distinctive box for your soap boxes or a custom eyelash box, die cut packaging lets you tailor the shape and design to suit the product perfectly.

Die cut packaging also ensures high efficiency in production.

The process can be automated, which reduces time and costs, particularly for large-volume orders.

Moreover, because the cutting process is precise, it minimizes material waste—making it a great option for businesses focusing on sustainability.

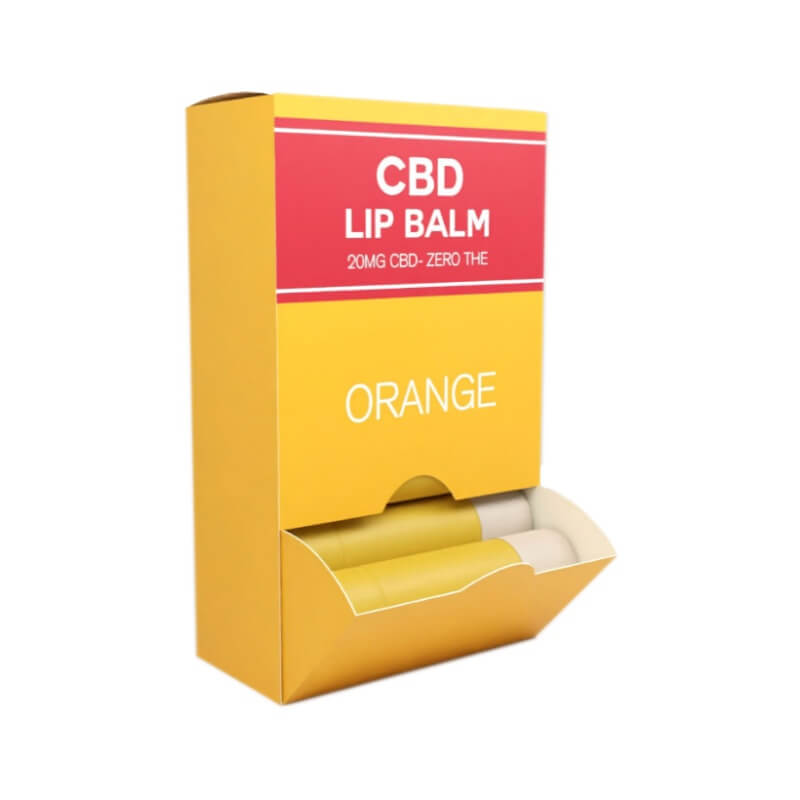

Additionally, die cut packaging offers versatility. From lip balm box packaging to custom die cut packaging for products like candles and nail varnish, the method provides both aesthetic appeal and functionality, enabling businesses to present their products in visually striking packaging while ensuring they remain durable and safe.

3. How Die Cut Packaging Boxes Are Revolutionizing Custom Cosmetic Packaging

The beauty and cosmetics industry has embraced die cut packaging for its ability to combine creative design with functionality.

Products like press-on nail boxes and lip gloss packaging benefit greatly from the flexibility and customization that die cutting offers.

For example, the process allows for packaging with intricate shapes, windows, and inserts that help present the product in an appealing, organized manner.

For packaging press-on nails, die cut boxes are often designed to hold individual nail sets, with compartments that securely display the product and prevent damage.

This customization can extend to the size, shape, and finishes used, ensuring that the final product matches the brand’s image and communicates quality.

Another benefit of die cut packaging in cosmetics is that it enables designers to create packaging that aligns with current trends while still being practical.

Whether it’s the packaging for soap boxes wholesale or for small-batch beauty products, die cut designs can reflect the brand’s aesthetics and draw in customers.

The die cut packaging for BD Safe-Clip is designed for convenient storage and portability of insulin syringes and needles.

4. Die Cut Packaging Design for Aesthetic and Functionality: Striking a Balance

One of the key benefits of die cut packaging is its ability to strike a perfect balance between aesthetics and functionality.

Die cut designs enable companies to craft packaging that not only stands out on the shelf but is also practical for everyday use.

For products like candle boxes with windows, die cut designs allow for unique openings and shapes that showcase the product inside.

This kind of packaging makes it easy for customers to see what they’re buying while still protecting the contents.

Whether you’re looking for elegant folds for nail varnish boxes or an intricate design for soap boxes, die cut packaging gives brands the flexibility to create functional packaging that is as visually appealing as it is protective.

In addition, the ability to incorporate special features like handles, inserts, or product windows into a die cut design means that brands can tailor the packaging to their specific needs, giving them the freedom to combine both beauty and utility in one package.

Springwater Soaps packaging featuring die cut windows for a beautiful, functional design that highlights the soap inside.

5. Eco-Friendly Options in Die Cut Packaging: Sustainable Materials and Practices

As sustainability continues to be a major priority in packaging, die cut packaging offers an excellent option for businesses looking to reduce their environmental impact.

The process uses materials like recycled paperboard, kraft paper, or biodegradable options, making it easy to create eco-friendly packaging solutions for various industries, including cosmetics.

Die cut packaging is often more sustainable than other types of packaging due to its precision and minimal waste.

Because the die cutting process is highly accurate, businesses can use the exact amount of material needed to create the packaging, reducing scrap and waste.

Additionally, many companies are now opting for die cut paper packaging boxes made from recycled or biodegradable materials to align with eco-conscious values.

For those in the cosmetics industry, using sustainable die cut packaging options, such as eco-friendly lip balm box packaging, not only demonstrates a commitment to the environment but also appeals to consumers who prioritize green practices when making purchasing decisions.

6. Creative Applications of Die Cut Box Packaging for Different Products

Die cut box packaging offers a wide range of creative possibilities, particularly when it comes to personalizing packaging for different products.

The precision of die cutting enables brands to craft unique and eye-catching packaging designs that enhance product presentation.

Whether you’re in the cosmetic, candle, or personal care industry, die cut packaging allows for tailored solutions that help products stand out.

Here are a few examples of how die cut packaging is creatively applied across various product categories.

Customize your press on nail box with the dazzling Emerald Swirl design, featuring green glitter and marble accents for a standout look.

When it comes to packaging press-on nails, die cut boxes are an excellent option for creating custom shapes that not only reflect your brand’s style but also provide protection for the delicate items inside.

With die cut designs, you can create compartments within the box that securely hold each set of nails in place, preventing any damage during transportation.

The box itself can be shaped uniquely to showcase the press-on nails, perhaps with a clear die-cut window that gives the customer a peek at the product.

The combination of aesthetic appeal and functionality makes die cut boxes perfect for this application.

Opt for eco-friendly wholesale soap boxes with a matte finish and high-quality printing, designed to protect and present your soaps beautifully.

Die cut packaging is also ideal for soap boxes, as it allows for creative shapes and personalized designs that reflect the brand’s image.

For example, a custom die cut soap box can include unique folds or decorative elements like embossed patterns or die-cut windows that showcase the soap inside.

Not only does this enhance the visual appeal, but it also protects the soap from damage while offering customers an elegant packaging experience.

Die cut packaging for soap boxes can be made from eco-friendly materials, aligning with the growing demand for sustainable packaging solutions.

For candle boxes with windows, die cut packaging provides an opportunity to incorporate functional and decorative elements into the design.

The window cutout, for instance, can be shaped to highlight the candle’s color, design, or scent, drawing customers’ attention immediately.

Die cut boxes for candles can also include intricate patterns or shapes, enhancing the overall presentation and elevating the product’s perceived value.

This type of packaging is not only aesthetically pleasing but also protective, as it helps secure the candle inside during shipping while showcasing it effectively.

In the beauty and cosmetics industry, die cut packaging is essential for creating sleek and functional designs.

For lip balm box packaging, die cut packaging allows for custom shapes that are both compact and eye-catching.

The design can include specific compartments or slots for holding individual lip balm tubes securely in place, ensuring they don’t shift or get damaged.

Additionally, die-cut windows or patterns can be incorporated to enhance the visual appeal of the packaging, making it more attractive to customers while ensuring easy access to the product.

Die cut packaging is also an excellent choice for lip gloss packaging, offering both creative design and protective qualities.

With die cut boxes, you can create elegant, custom-shaped packaging that aligns with your branding while keeping the lip gloss secure.

For example, the box can be die-cut to include unique folds or designs that match the glossy finish of the lip gloss itself.

This not only adds to the luxury feel but also creates a memorable unboxing experience for customers.

A well-designed die-cut box for lip gloss can elevate the product and attract consumers looking for high-quality, beautifully packaged beauty items.

When it comes to nail varnish boxes, die cut packaging allows for intricate designs that complement the colorful and stylish nature of nail products.

The precision of die cutting means that brands can create custom shapes that fit the size and style of the nail varnish bottle perfectly.

This could include a custom insert within the box to hold the bottle securely or a die-cut window to showcase the color of the varnish.

Additionally, the box itself can be designed with unique die-cut details, such as patterns or embossing, to add a high-end touch that appeals to fashion-forward consumers.

For custom eyelash boxes, die cut packaging provides an opportunity for highly creative designs that cater to the beauty industry’s demand for elegant, luxurious packaging.

Die cut boxes for eyelash packaging can include features like custom compartments to hold the lashes securely, intricate die-cut shapes for a unique look, and even windows that display the lashes in an appealing way.

Whether it’s a sleek box with a die-cut logo or a more elaborate design featuring decorative patterns, die cut packaging helps enhance the brand’s image and offer an unforgettable presentation.

7. FAQ

1. What is die cut packaging?

Die cut packaging is a custom packaging method that uses a specialized metal die to cut materials like paper, cardboard, or plastic into specific shapes or designs. This process allows businesses to create unique, tailored packaging that fits their product’s size, shape, and branding requirements.

2. How does the die cutting process work?

In the die cutting process, a metal die (a sharp mold) is pressed onto the packaging material, cutting it into a predefined shape. The die can be designed to create intricate cuts, folds, and perforations, giving brands the ability to produce custom shapes, windows, and designs with great precision.

3. What are the benefits of using die cut packaging?

Die cut packaging offers several benefits:

Customization: Allows for precise, unique shapes and designs that fit your product perfectly.

Versatility: Works with various materials, including paper, cardboard, and plastics.

Cost-effectiveness: Ideal for large production runs, as it’s efficient and reduces waste.

Aesthetic appeal: Provides an opportunity for eye-catching designs that reflect your brand’s identity.

Functionality: Offers excellent protection for products, particularly delicate or fragile items.

4. Is die cut packaging eco-friendly?

Yes, die cut packaging can be eco-friendly. The die cutting process is precise, which minimizes material waste, and businesses can opt for sustainable materials such as recycled paperboard or biodegradable options. Additionally, many brands are turning to eco-friendly inks and finishes, ensuring their die cut packaging aligns with sustainability goals.

5. What types of products are best suited for die cut packaging?

Die cut packaging is perfect for products that require custom shapes, branding, or added protection. Common products that use die cut packaging include:

Cosmetics (e.g., lip gloss, lip balm, eyelash boxes)

Personal care products (e.g., soap boxes, candles)

Health and wellness items (e.g., press-on nails, nail varnish)

Luxury goods requiring high-end, unique packaging

6. How is die cut packaging different from regular box packaging?

Unlike standard box packaging, which is typically made using pre-set molds and basic cuts, die cut packaging offers precision and flexibility. The die cutting process allows for intricate shapes, custom windows, and unique designs that cannot be achieved with standard methods. Die cut packaging is highly tailored to specific products, offering more creativity and adaptability.

7. Can die cut packaging be used for small product batches?

Yes, die cut packaging is ideal for both small and large production runs. While it’s commonly used for large-scale orders due to its cost-efficiency, small businesses can also take advantage of die cut packaging. With the right setup, die cut packaging can be produced in smaller batches with minimal waste.

8. What materials can be used for die cut packaging?

Die cut packaging can be made from a wide variety of materials, including:

Paperboard and cardboard: Ideal for lightweight and durable packaging.

Kraft paper: A sustainable option for eco-friendly packaging.

Plastic and acetate: Used for clear packaging or boxes with windows.

Foam inserts: Commonly used to hold products securely, such as in custom eyelash boxes or press-on nail boxes.

9. How can I customize the design of my die cut packaging?

Customization is a key feature of die cut packaging. You can customize your design by:

- Choosing the shape and size of the packaging.

- Adding custom die-cut windows, folds, and perforations.

- Selecting special finishes like embossing, debossing, or foil stamping.

- Printing your brand’s logo, colors, and artwork directly on the packaging material.

10. What is the cost of die cut packaging?

The cost of die cut packaging depends on several factors, including the complexity of the design, the materials used, and the quantity ordered. Generally, die cut packaging becomes more cost-effective as the order quantity increases due to economies of scale. However, for small runs, the setup cost may be slightly higher due to the creation of the custom die.

11. Can I use die cut packaging for products that need to be shipped?

Yes, die cut packaging is often used for shipping, as it provides an excellent balance of protection and presentation. Many products like nail varnish boxes and lip balm boxes use die cut designs to ensure the product is securely held in place during transport while offering a visually appealing packaging experience for customers.

12. How do I get started with custom die cut packaging for my products?

To get started with custom die cut packaging, you’ll want to:

- Work with a packaging manufacturer or designer who specializes in die cutting.

- Provide the necessary details about your product, such as dimensions, material preferences, and any design ideas you have.

- Choose the style and features of the packaging (e.g., compartments, windows, folds).

- Review a sample or prototype before proceeding with a full production run.

In conclusion, die cut packaging offers an unparalleled combination of creativity, functionality, and customization that makes it an ideal choice for businesses looking to enhance their product presentation.

Whether you’re designing packaging for cosmetics, candles, or personal care items, die cut packaging allows for unique shapes, custom designs, and precise features that not only protect your products but also elevate your brand’s identity.

By choosing die cut packaging, you’re investing in a solution that adds value, appeals to consumers, and aligns with the growing demand for sustainable, eco-friendly packaging options.

With endless possibilities, die cut packaging stands out as a versatile and essential tool for businesses looking to make a lasting impression in today’s competitive market.