How to Measure a Box: Get Accurate Dimensions Easily

When it comes to packaging—whether you’re shipping products, designing custom packaging, or optimizing shipping costs—measuring a box correctly is key to success.

Getting the right box dimensions not only helps avoid unnecessary shipping charges but also ensures your items are secure and protected.

Whether you’re a business owner, an e-commerce seller, or just looking to organize your home, this guide will walk you through how to measure a box like a professional.

In this definitive guide, you’ll learn the gold standard for box measurements, common mistakes to avoid, and industry-specific tips for accuracy.

By the end, you’ll be equipped with all the knowledge you need to measure a box for shipping, storage, or custom packaging needs.

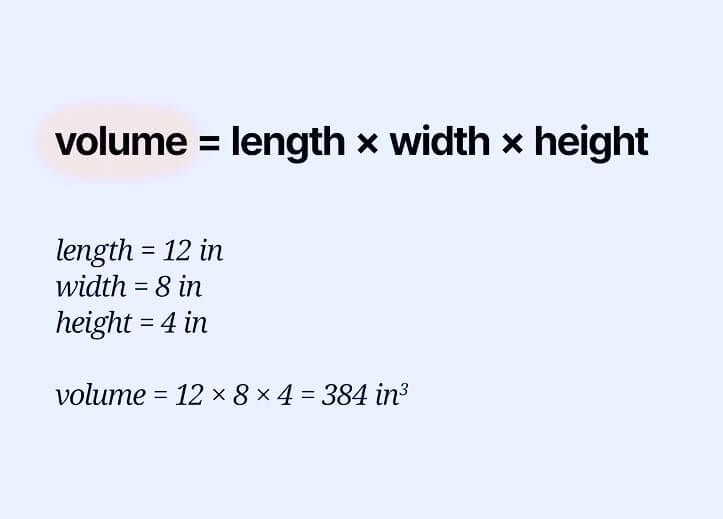

The Gold Standard: Length x Width x Height

When you measure a box, there’s a consistent formula to follow: Length x Width x Height.

These three measurements are the foundation for nearly all box-related calculations, whether for shipping, storing, or custom packaging.

1 Length (L): The Longest Side

The length is the longest side of the box. This is the dimension you measure from one end to the other along the longest edge of the box.

It’s essential to measure this side first to maintain consistency and ensure you’re using the correct measurement for the rest of your packing or shipping needs.

2 Width (W): The Shorter Side

Next, measure the width, which is the shorter side of the box.

This dimension is the one perpendicular to the length, so make sure you’re measuring from edge to edge along the shortest side.

3 Height (H): The Vertical Dimension

Finally, measure the height, which is the vertical dimension from the bottom of the box to the top edge.

This measurement is especially important when stacking or storing boxes, as it determines the clearance needed for safe handling.

Accurately calculator your packaging’s volume with this easy-to-use measurement tool.

Pro Tip for Precision

- For small boxes (<12”): Use metal calipers for precise measurements.

- For larger boxes: A flexible fabric tape measure works best.

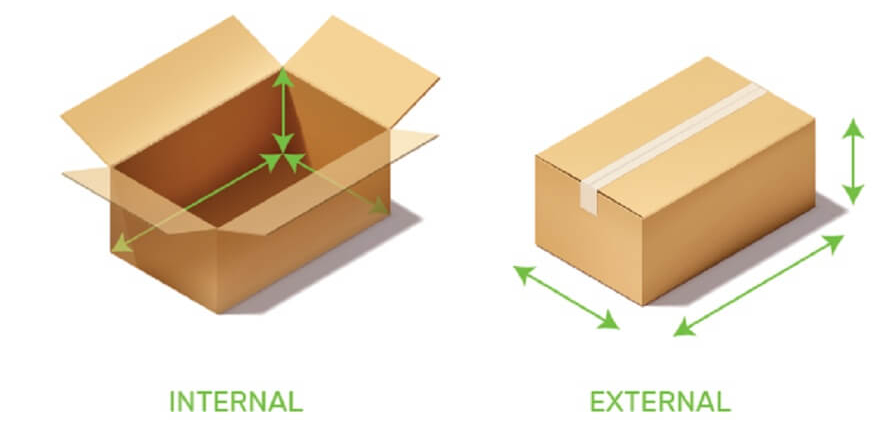

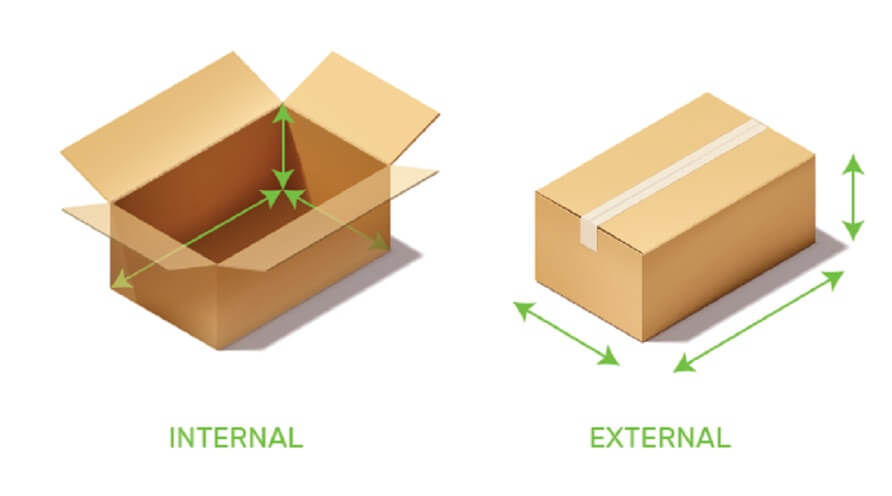

Critical Differences: Internal vs. External Dimensions

It’s important to understand that there’s a difference between internal and external dimensions. Depending on your needs (shipping, product fit, etc.), both measurements are necessary.

| Measurement Type | When It Matters | Tolerance |

| Internal | Product fit, cushioning, internal space | +1/8″ – 1/4″ |

| External | Shipping costs, pallet stacking, outer dimensions | Exact |

Case Example: If you’re measuring a 12″ internal height box, the external height will likely be 12.25″ to account for the thickness of the box’s walls.

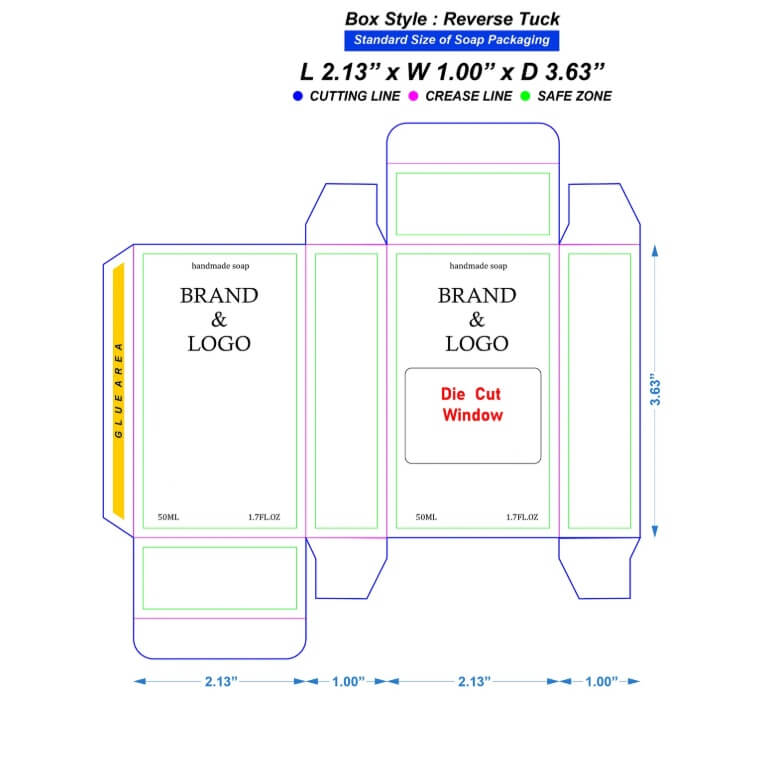

Specialized Box Measurements

Different types of boxes and packaging styles require specialized measurements. Here’s how to measure them accurately:

1 Corrugated Mailers & Folding Cartons

- Always measure when the box is fully assembled.

- Don’t forget to include flap extensions in your height measurement.

- Measure cavity dimensions if you’re dealing with trays for product placement.

- Pay attention to wall angles if they exceed 10° as this can affect the fit.

3 Shipping Boxes

- Use external dimensions for shipping calculations.

- Measure diagonally to check for squareness—this is especially useful for irregularly shaped boxes.

5 Costly Mistakes to Avoid When Measuring a Box

If you want to ensure your packaging is both functional and cost-effective, avoid these common mistakes:

- Measuring Empty vs. Loaded Boxes

Solution: Test your measurements with actual products and any necessary padding to ensure a secure fit. - Ignoring Dimensional Weight

Smart Trick: Use the formula (LxWxH) ÷ 166 to calculate shipping costs for USPS. - Forgetting Seam Allowances

Key Data: Standard seams add approximately 1/2″ – 3/4″ to the overall size. - Mixing Imperial and Metric Units

Pro Tip: Use dual-scale measuring tools to keep measurements consistent and avoid conversion errors. - Overlooking Temperature Effects

Expert Insight: Corrugated boxes expand by 0.5% per 20°F increase, so measure in a temperature-controlled environment when possible.

Industry-Specific Pro Tips

Different industries have specific requirements for box measurements. Here are some pro tips for custom packaging needs:

For Cosmetic Packaging

- Add 1/8″ to the internal dimensions of push-up trays to ensure smooth operation.

- Measure pump stems separately to comply with CLP (Classification, Labelling and Packaging) regulations.

For E-Commerce Packaging

- Match the inner dimensions of the box to the product size, adding a 3mm buffer for easy packing.

- Use nesting box sizes to reduce the number of SKUs, saving space and shipping costs.

Why Precision Matters: The Impact of Incorrect Measurements

Even a small error in your box measurements can cause significant issues:

- A 1/4″ error in box dimensions can lead to:

-

- 18% higher shipping costs (according to FedEx data).

- 22% reduced pallet stacking efficiency

- 3% more product damage during transit

Correct measurements not only save you money but also ensure the safety and integrity of your products.

FAQ: Frequently Asked Questions

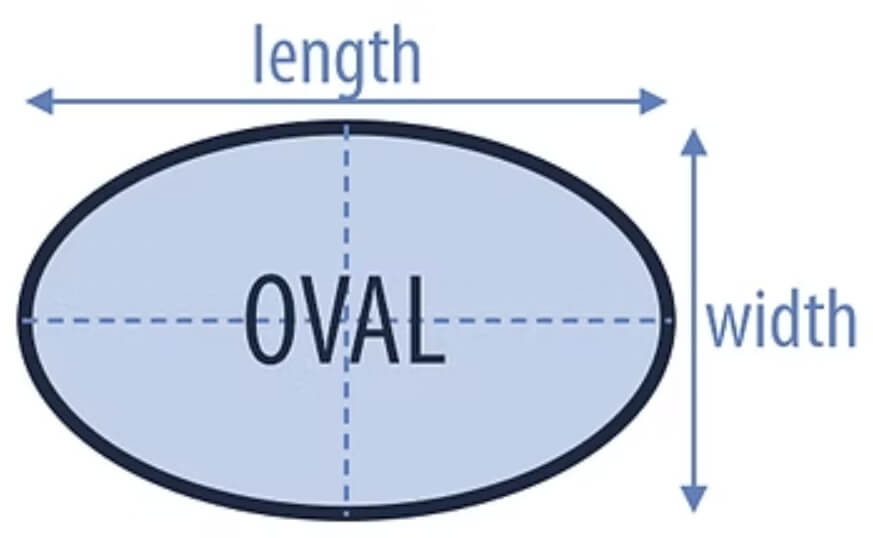

Q: How do I measure oval boxes?

A: For oval boxes, measure the major axis (the longest length) for the length, the minor axis (the shortest width) for the width, and the vertical height as usual. Make sure to account for the shape of the box by measuring both axes to get the most accurate results.

Q: Should I measure boxes with logos and print?

A: It’s best to measure blank boxes first, before applying logos or prints. Print and logo coverage can slightly alter the overall dimensions, so measuring the base box will give you the most accurate measurement for packing and shipping.

Q: How do I measure a box with a flap or tuck?

A: When measuring boxes with flaps or tucks (like folding cartons or corrugated mailers), include the flap extensions in your height measurement, as these add to the box’s overall dimensions. For length and width, measure the open edges of the box as usual.

Q: What if my box has irregular or asymmetrical sides?

A: For boxes with irregular sides, measure the longest length, widest width, and tallest height at their most extended points. If the box is significantly out of shape, consider measuring diagonally to ensure the box is square and won’t cause issues when stacked or transported.

Q: Can I use the same measurements for custom packaging as for regular shipping boxes?

A: Not always. Custom packaging, especially for retail or high-end products, may require different measurement standards. For instance, custom boxes often have additional padding or internal dividers that affect the internal dimensions. Always measure both external and internal dimensions to ensure a proper fit, particularly if you’re creating bespoke packaging for a product.

Conclusion

Mastering how to measure a box is crucial for everything from shipping costs to product safety. Whether you’re working with corrugated boxes, die-cut trays, or custom cosmetic packaging, understanding the right measurements will streamline your processes and save you money. From choosing the right tools to avoiding common mistakes, this guide has covered the essentials you need for perfect box measurements every time.

Need Custom Boxes?

If you’re in need of precise box measurements for your business, we can assist you with professional advice and custom packaging solutions. Reach out for help!