Offset Printing vs. Digital Printing for Custom Cosmetic Packaging: Which is Best?

When it comes to creating stunning custom cosmetic packaging, the printing method plays a vital role in achieving the perfect look and feel.

At Custom Beauty Box, we offer two primary printing techniques: offset printing and digital printing, both tailored to meet your brand’s unique needs.

But which method is best for your packaging? Let’s explore the differences and help you decide.

What is Offset Printing?

Offset printing is a well-established printing method that transfers ink from a plate to a rubber blanket and then onto the packaging material.

This process is known for its high-quality output and cost efficiency, especially for large print runs.

Key Benefits of Offset Printing for Cosmetic Packaging:

- Superior Color Accuracy: Offset printing delivers highly accurate color reproduction, which is crucial for brands that require consistent, vibrant colors for custom cosmetic packaging.

- Cost-Effective for Bulk Orders: If you need to print large quantities of packaging, offset printing becomes more affordable as the unit cost decreases with volume.

- Exceptional Detail: With offset printing, intricate designs, fine details, and small text are reproduced with precision, offering a premium finish.

What is Digital Printing?

Digital printing is a modern technique that prints directly from digital files onto the packaging material, without the need for printing plates. This makes digital printing a quick and flexible solution, especially for short-run projects and customization.

Key Benefits of Digital Printing for Cosmetic Packaging:

- Quick Turnaround: Since there are no plates to create, digital printing is a faster process, making it ideal for projects with tight deadlines.

- Perfect for Small Runs: For smaller quantities, personalized packaging, or limited-edition designs, digital printing is more cost-effective.

- Customization Flexibility: Digital printing allows for easy changes between prints, so if you need different packaging designs, this method is the best choice.

Why We Use Digital Printing for Sample Orders

At Custom Beauty Box, we use digital printing for sample orders. This allows us to quickly provide you with a prototype of your custom cosmetic packaging. However, it’s important to note that samples may have slight color differences compared to mass production, which is done using offset printing. The primary goal of these samples is to give you an accurate idea of the size, dimensions, quality, and approximate design effect before you proceed with larger orders.

Offset Printing vs. Digital Printing: Which Should You Choose?

At Custom Beauty Box, we understand that every packaging project is unique, so choosing between offset and digital printing depends on your specific needs. Here’s a comparison to help you decide:

Printing Machines Comparison: Offset vs. Digital

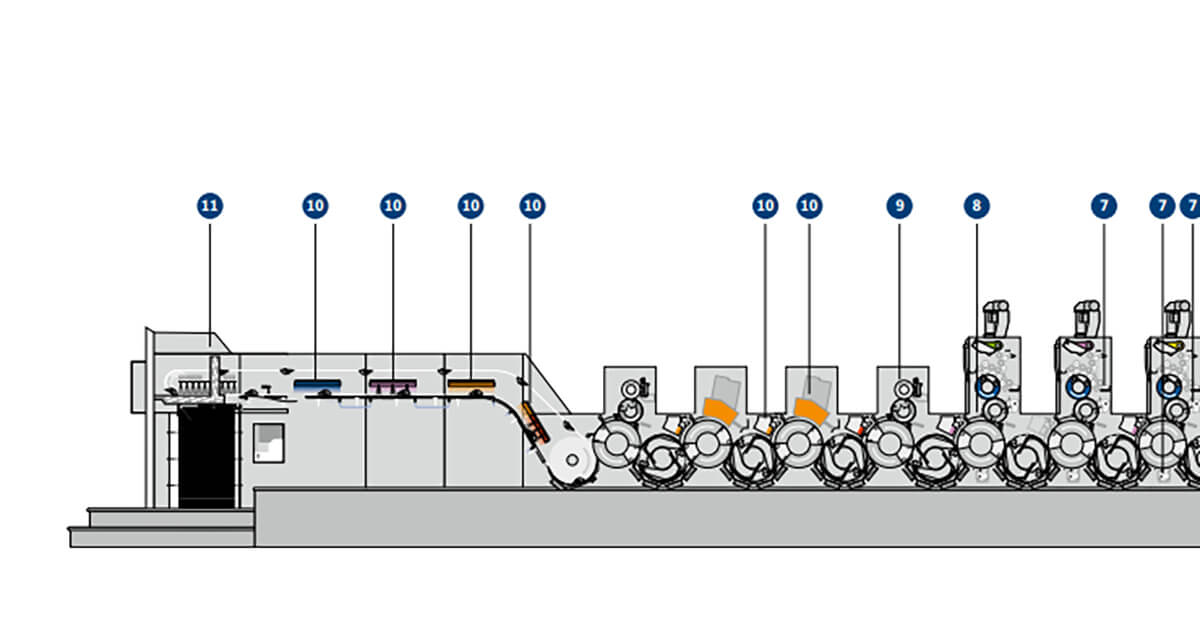

Offset Printing Machines are complex systems that rely on a multi-step process to achieve their high-quality output. These machines use a series of metal or polymer plates—one for each color (typically Cyan, Magenta, Yellow, and Black, or CMYK)—to transfer ink to a rubber blanket, which then applies the ink to the printing surface. Offset machines are equipped with multiple ink rollers, which ensure even ink distribution, resulting in consistent color and sharp details, even in large volumes.

Key Features of Offset Printing Machines:

- Plate-Based System: The use of plates makes this machine ideal for large print runs, where the upfront cost of creating plates is spread out over the high volume of prints.

- Ink Control and Calibration: These machines have sophisticated ink management systems, allowing for precise control over ink density and color blending, ensuring near-perfect color accuracy across all units.

- Large Format and Speed: Offset printing machines can handle larger sheets of material at high speeds, making them optimal for high-volume jobs like bulk cosmetic packaging production.

Digital Printing Machines, in contrast, operate without the need for plates, printing directly from digital files using inkjet or laser technology. These machines are designed to handle smaller quantities with more flexibility and allow for quick changes in print design. Rather than using physical plates, digital printers apply toner or liquid ink directly to the substrate, often in a single pass.

Key Features of Digital Printing Machines:

- On-Demand Printing: Because there’s no plate creation or extensive setup, digital machines are perfect for smaller, customized orders or sample production. They can quickly switch between jobs, making them flexible for short runs.

- Variable Data Printing: Digital machines excel in jobs that require customization, such as personalized packaging with varying designs or texts, which can change from one unit to the next without slowing down the printing process.

- Color Consistency: While offset machines offer better overall color control, modern digital printing machines have advanced color management systems, reducing the gap in quality for small to medium jobs. However, for very large print areas or highly detailed color matching, offset still holds an edge.

Choose Offset Printing If:

- You Need Large Quantities: For high-volume orders, offset printing is the most cost-efficient and consistent option.

- Color Accuracy is Essential: If exact color matching is critical to your brand identity, offset printing provides the highest color fidelity.

- You Have Intricate Designs: Offset printing offers sharper detail for complex packaging designs and small text.

Choose Digital Printing If:

- You Have a Tight Deadline: Digital printing is faster, making it ideal for urgent projects.

- You Need Small Runs: For limited editions, seasonal packaging, or personalized designs, digital printing is more economical.

- Flexibility is Key: Digital printing allows for quick changes in design, perfect for brands experimenting with different looks.

Why Samples May Have Color Differences?

When you order a sample from Custom Beauty Box, we use digital printing to deliver a fast and cost-effective prototype. However, because our mass-production process uses offset printing, there might be slight color variations between the sample and the final product. The purpose of the sample is to help you evaluate the size, dimensions, and quality, ensuring that you are satisfied with the packaging’s overall look before proceeding with bulk production.

FAQs

- What is offset printing in cosmetic packaging?

Offset printing is a high-quality printing method that is ideal for large print runs. It provides precise color accuracy and sharp details, making it perfect for custom cosmetic packaging. - What are the advantages of digital printing for cosmetic packaging?

Digital printing offers fast turnaround times and is more cost-effective for small quantities. It’s also highly flexible, allowing for quick changes in design. - Why are digital printing samples different in color from the final product?

Digital printing samples may show slight color differences compared to the final product because mass production uses offset printing, which offers more accurate color reproduction. - Which printing method is best for large cosmetic packaging orders?

For large orders, offset printing is the best choice due to its cost efficiency and consistent quality across all units. - Can I get custom packaging samples with digital printing?

Yes, at Custom Beauty Box, we provide samples using digital printing so you can review the size, quality, and approximate design before placing a full order.

Custom Printing at Custom Beauty Box

At Custom Beauty Box, we offer both offset printing and digital printing to meet the diverse needs of your brand. Whether you require high-volume, exact color reproduction or small, customized print runs, we are here to help. Our expert team can guide you in choosing the best printing method for your project, ensuring your cosmetic packaging stands out on the shelves.

Contact us today to get started on your custom cosmetic packaging project!