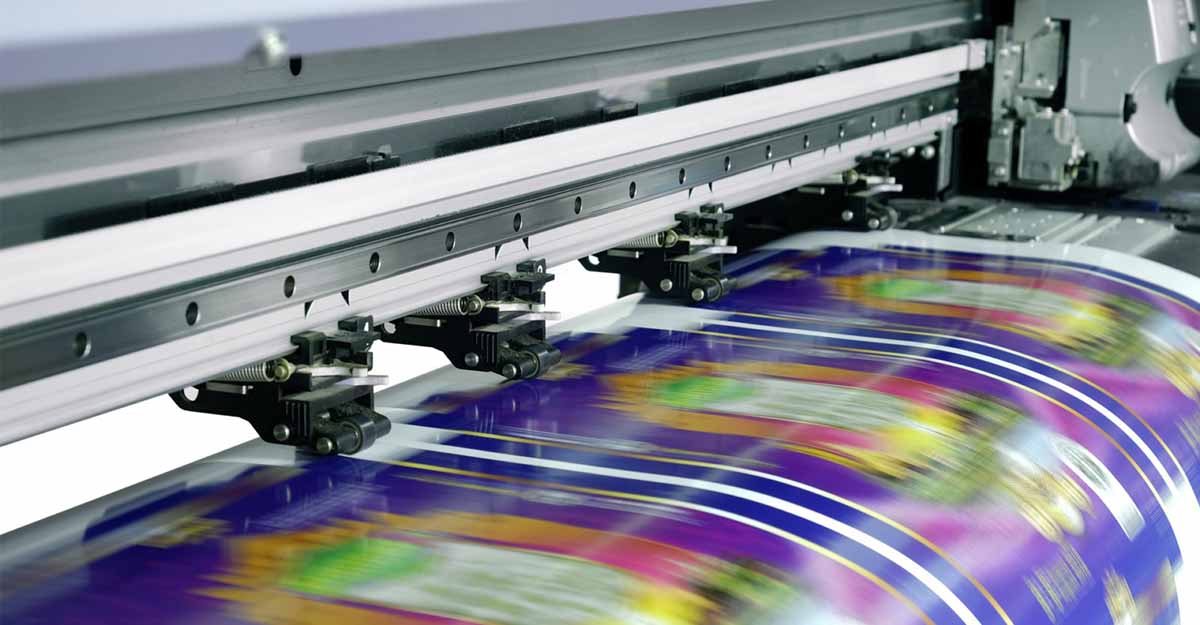

Paper Printing Methods – What Is The Difference Of Various Printing Methods

What are the classifications of paper printing methods?

This post will introduce the specific classification content in detail for you.

There are many types of printing methods.

If we decide on printing methods for different printing purposes, we can divide them into book printing, packaging printing, advertising printing, and superior printing.

If we classify them according to the number of printing colors, we can divide them into monochrome printing and multi-color printing. We can organize them into letterpress printing, gravure printing, offset printing, and stencil printing by the type of printing plate. Since the type of printing plate is closely related to the printing process and can better reflect the characteristics of various printing methods, the classification of printing plates is more common.

In the printing process, printing has two categories: pressure printing and pressureless printing. However, due to the continuous emergence of new materials, people’s various demands for printing are increasing. The use of pressure printing and non-pressure printing can not achieve copy conversion, so superior printing has emerged.

1 Pressure Printing Methods

The transfer of ink and colorant to the substrate is called pressure printing. Due to the printing plate’s characteristics, pressure printing comes from two forms: direct printing and indirect printing.

(1) Direct printing. The graphic part on the printing plate is directly transferred to the substrate for printing.

(2) Indirect printing. The printing machine will firstly transfer the design on the printing plate and then to the substracts

2 Letterpress Printing Methods

Letterpress printing is an older printing method, which originated from wood carvings in the Tang Dynasty. The printing plate’s graphic part protrudes from the blank part of the same plane in relief printing, but it is recessed in the horizontal plane. In the printing process, the ink is applied to the font or image’s surface through pressure, and the ink is transferred to the printing surface to form embossed relief printing, which belongs to direct printing.

3 Gravure Printing

Gravure printing originated from the engraved copper plate in the middle of the 5th century, which carved figures manually or mechanically to form a concave figure plane. The production principle is opposite to letterpress printing. That is to say; the graphic part is lower than the plane and blank of the printing plate. When printing on the flat surface, the ink on the printing plate is first scraped off, and the concave graphic part remains, and then pressurized Press part of the ink on the substrate’s surface. Gravure printing is direct printing, mainly used for printing.

4 Offset Printing

First, wetting the entire printing plate with water to make the empty part absorb water, and then coating the ink on the original container. Because the blank portion is hydrophilic and oleophobic, and the graphic part is lipophilic and hydrophobic, the ink on the printing plate absorbs the visual element’s surface. The printing plate is then mechanically brought right into contact with the substratum and pressure related to making the ink-friendly. The image part is transferred to the surface of the substrate object.

Lithographic printing is also called offset printing. Since lithographic printing is based on the principle of incompatibility between oil and water, the blank part of the printing plate is firstly hydrophilic and partly lipophilic. Therefore, the blanket cylinder can be installed on a lithographic printing machine to first transfer the printing plate’s graphic part to the blanket cylinder and then press the blanket cylinder and the substrate together for printing, which avoids the gap between the printing plate and the substrate. Offset printing is also called offset printing, which is a modern indirect printing method.

5 Hole Printing Methods

In stencil printing, the number of pictures and texts on the printing plate are different, and the meshes of different or equal sizes of cavities are composed of meshes. In printing, the substrate is placed on the coating, and the ink is scraped under the squeegee under the self-inking printing plate. It is transferred to the substrate’s surface through the mesh, and grids of different or equal mesh sizes are placed on the printing plate coated with self-ink, and the ink is transferred to the substrate’s surface through the mesh. The stencil printing is direct. The smaller the printing plate’s graphic part is, the more the number of prints, the finer and more realistic the image, and vice versa.

Sleeve printing includes a screen printing reputation printing plate and a hollow printing plate. Screen printing is the primary printing method in modern design.

(1) Screen Printing

Screen printing is a more commonly used method in orifice printing. Tighten the wire mesh on the thousand-mesh frame and make a mesh template on the silk dysentery to block the non-image part. The image and text part’s mesh can leak from the image’s mesh and text through the ink and the scraping pressure of the scraper. The traditional method of plate making is handmade to the substrate, and the technique of optical plate making is a method commonly used in modern times. In this plate making method, the screen is tied to the screen frame with silk support, and then a photosensitive cavity is coated on the screen to form a photosensitive adhesive film. The graphic base plate is then densely printed on the adhesive film printing plate, and the printing plate is formed by exposure, development, and washing. For the images that need to be over-inked on the printing plate, some meshes are not closed, and the ink forms ink marks on the substrate through the meshes during printing.

(2) Prestigious Printing

The principle of Handwriting printing is different from the direction of screen printing. Handwriting printing does not use screen printing to make a pattern. The prestigious version includes three forms: hand-carved wax version, typing wax version, and scanning wax version. It was first used in office printing organizations and schools to print documents.

(3) Hollow Printing

Hollow printing is an ancient printing technique. Both Chinese folk blue calico and batik are printed by hollowing technology to engrave the base’s image and use ink or color spray to complete the printing on the substrate. At present, most of the hollow boards are cardboard, plastic sheets, iron sheets, etc., which are mainly used for sign printing, such as packaging wooden box signs, road signs, and stop signs.

The above is the detailed classification of printing introduced.