Spot UV Printing: Add Glossy Precision to Your Designs

Spot UV is a coating technique (not a printing method) that adds a glossy, raised finish to specific areas of printed materials.

By curing a clear varnish with ultraviolet (UV) light, Spot UV creates striking contrasts between glossy and matte surfaces, delivering both visual and tactile appeal.

At custombeautybox.com, we specialize in harnessing this technique to transform packaging and branding materials into luxurious, memorable experiences.

Below, we unpack how Spot UV works, its applications, and why it’s a game-changer for designers and brands.

Understanding Spot UV: Coating vs. Printing

Spot UV is not a printing technique; it’s a finishing process applied after printing. Here’s how it stands out:

- What it does: A UV-curable varnish is selectively applied to chosen areas (e.g., logos, text, patterns), then exposed to UV light to harden instantly.

- Visual effect: Creates a high-gloss, reflective finish that contrasts sharply with untreated matte surfaces.

- Tactile feel: Adds a raised, smooth texture to designs, enhancing sensory engagement.

For example, a business card with a matte base and a Spot UV-coated logo instantly feels premium, drawing attention to the brand’s identity.

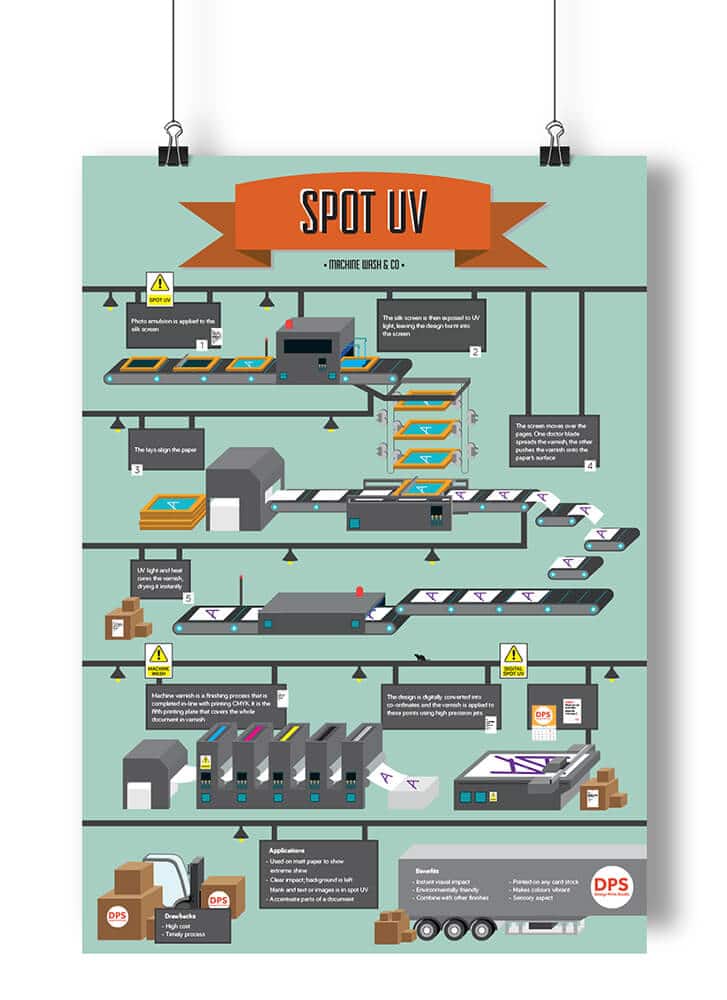

How Does Spot UV Work? The Role of UV Light

The magic of Spot UV lies in UV curing:

- Application: A clear varnish is applied to specific areas using a template or digital mask.

- Curing: UV light triggers a photochemical reaction, hardening the varnish in seconds.

- Result: A durable, scratch-resistant finish that won’t yellow or fade over time.

This process allows for pinpoint precision, making it ideal for intricate designs like foil-stamped cosmetics packaging or textured brand patterns.

Applications of Spot UV: Where Shine Meets Strategy

Spot UV’s versatility shines across substrates and industries. Below are key use cases we’ve perfected at custombeautybox.com:

1 Elevating Matte Finishes

Spot UV pairs perfectly with matte lamination or soft-touch matte coatings to create dramatic contrasts. Examples include:

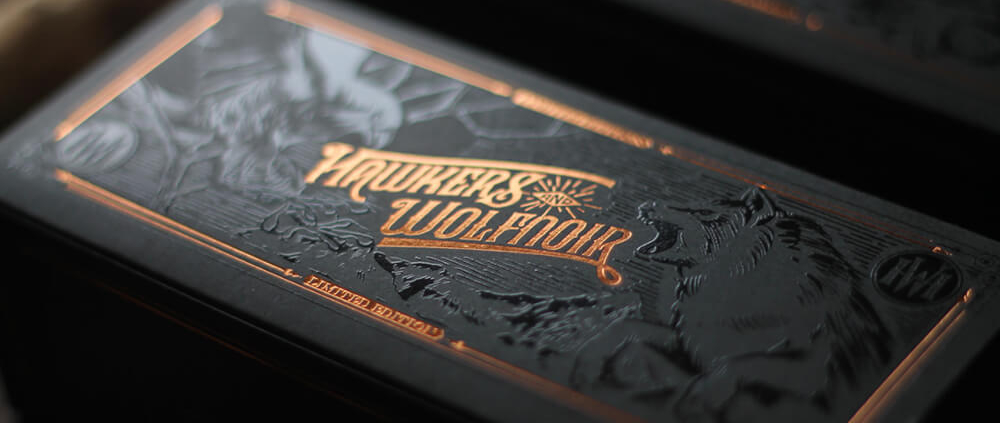

- Luxury packaging: High-end beauty boxes (like our custom hair packaging solutions) with glossy logos against velvety matte backgrounds.

- Book covers: Textured titles that stand out on matte-coated covers.

- Brochures: Highlighting key product features with tactile gloss accents.

Pro Tip: Darker, matte substrates (e.g., deep blue, charcoal) maximize Spot UV’s visual impact.

2 Customization Options

Tailor Spot UV to your project’s needs:

- Design areas: Coat entire sections (e.g., borders) or tiny details (e.g., icons).

- Layer thickness: Adjust viscosity for subtle textures or bold 3D effects.

- Finish types: Combine gloss Spot UV with softer matte/dull varnishes for dynamic layering.

Benefits of Spot UV: Beyond Aesthetics

Spot UV isn’t just eye candy—it’s a strategic tool for brands:

- Tactile engagement: Consumers instinctively touch Spot UV details, deepening brand interaction.

- Brand differentiation: Premium finishes signal quality, helping products stand out on shelves.

- Durability: UV-cured coatings resist scratches, moisture, and everyday wear.

A study by Packaging Digest found that 72% of consumers associate textured packaging with higher product value—making Spot UV a smart investment for luxury beauty brands.

Key Considerations for Spot UV Success

To maximize results, keep these factors in mind:

1 Substrate Compatibility

- Best for: Thick, stable materials like coated paperboard, PVC, or laminated stocks.

- Avoid: Thin papers prone to warping during curing.

2 Design Optimization

- Simplify details: Fine lines or tiny text may not cure evenly.

- Contrast matters: Use Spot UV on dark or richly colored backgrounds for maximum “wow” factor.

3 Budgeting

Costs scale with coverage area and complexity. To save, focus Spot UV on critical branding elements (e.g., logos).

The Spot UV Process: From Concept to Cure

At custombeautybox.com, we follow a streamlined workflow:

- Mask file prep: A digital template ensures precision (vector paths work best!).

- Offset/digital printing: Your design is printed first; Spot UV is added afterward.

- Varnish application: The UV coating is rolled or sprayed onto targeted zones.

- Curing: UV lamps harden the varnish instantly for rapid turnaround.

This process integrates seamlessly with both offset (ideal for large runs) and digital printing (perfect for shorter, customized orders).

Conclusion: Shine Brighter with Spot UV

Spot UV is the secret weapon for brands seeking to blend sophistication with functionality. Whether you’re crafting high-end beauty boxes, premium business cards, or eye-catching brochures, this coating technique elevates designs through bold contrasts and irresistible textures.

Ready to explore Spot UV for your next project? Contact custombeautybox.com to discover how we transform ordinary prints into extraordinary brand experiences.

FAQs

Q: Can Spot UV be combined with foil stamping?

A: Absolutely! Pairing Spot UV with metallic foils creates ultra-luxe effects—perfect for limited-edition beauty packaging.

Q: Is Spot UV eco-friendly?

A: Many UV varnishes are low-VOC and recyclable. Ask our team about sustainable coating options!